PRODUCTS

When your worksite needs high-performing and durable access products, GFI Solutions is here to help! Your access products need to be able to last through challenging terrain, heavy equipment, and more. GFI Solutions has the access solutions you need to ensure the navigability and safety of your site. Below we’ll cover the range of products GFI proudly offers.

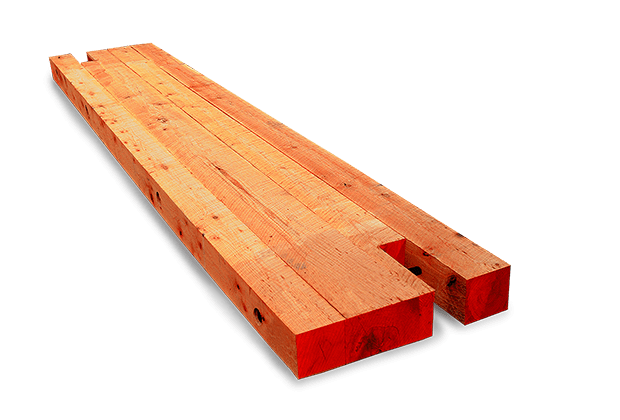

CLT Mats

GFI Solutions’ SiteSafe™ Cross Laminated Timber (CLT) mats are unrivalled in their reliability and performance. Manufactured from sustainably sourced Southern Yellow Pine, our CLT mats are stroger, lighter and longer lasting than any other conventional matting option available on the market. If your worksite needs an cost effective, high-quality, durable access matting solution, GFI Solutions’ SiteSafe™ CLT mats are your best choice.

Access Mats

Wooden access mats are an industry standard for safe site access solutions. At GFI Solutions, we have a range of access matting solutions, including rental access mats, custom-sized mats, and more! If you’re looking for a simple way to ensure your equipment and crew can easily access and navigate your worksite, GFI Solutions is here to help.

Rig Mats & Crane Mats

When your moving heavy loads, you need matting solutions that can withstand the weight of heavy equipment and machinery. At GFI Solutions, we are proud to offer various rig and crane mat solutions built to last against even the heaviest loads. Regardless of the terrain you’re trying to navigate, GFI Solutions has the rig and crane mats you need to get the job done.

Find out more about our rig mats here and our crane mats here! ❯

Temporary Access Bridges

If your remote worksite needs a reliable solution for crossing ditches, rivers, and other challenging terrains, GFI Solutions’ temporary access bridges are a great option! Our temporary access bridges allow your crew and equipment to quickly and safely navigate over gaps in the landscape you’re trying to navigate through.

Learn more about GFI Solutions’ temporary access bridges here! ❯

Ready to Learn More?

As Western Canada’s leading source of safe site access solutions, GFI Solutions is proud to offer our customers a comprehensive inventory of access solution products. In addition to our range of products, GFI Solutions also offers 24/7 sales service, mat rentals, mat washing, deliveries, installation, mat washing and more.

Find out more about our products and services!

Frequently Asked Questions

HOW DOES THE CONSTRUCTION OF SITESAFE™ CLT MATS MAKE THEM MORE DURABLE?

WHY IS IT IMPORTANT THAT SITESAFE™ CLT ACCESS MATS IS AN ENGINEERED PRODUCT?

WE NEED MATS THAT CONNECT; IS THAT POSSIBLE WITH SITESAFE™ CLT ACCESS MATS?

SiteSafe™ CLT access mats can be fitted with interconnecting fingers that work in the same manner as traditional bolted access mats.

WHAT SIZES ARE AVAILABLE?

Currently, SiteSafe™ CLT access mats are available in 3, 5, and 7-ply construction

- SiteSafe™ 300 CLT access mat 3-ply – 8′ x 14′

- SiteSafe™ 500 CLT access mat 5-ply – 8′ x 16′

- SiteSafe™ 700 CLT access mat 7-ply- 8′ x 16′

ARE SITESAFE™ CLT MATS SAFE FOR THE ENVIRONMENT, INCLUDING WETLANDS?

Yes, in fact they are superior in promoting environmental stewardship. The adhesive becomes chemically inactive prior to leaving the facility, presenting no harm to the environment. (The metals in bolted mats oxidize, leaching contaminants into the ground and creating disposal difficulties.)

The raw materials in SiteSafe™ CLT access mats are farmed in approximately 20 years, where the hardwood species used in bolted mats can take 80-100 years to regrow.

Additionally, the solid surface and adhesive barriers between layers don’t allow invasive species to embed themselves into the mats like with traditional mats.

HOW WILL SITESAFE™ CLT ACCESS MATS PERFORM IN EXTREME OR LESS-THAN-IDEAL CONDITIONS?

SiteSafe™ CLT access mats have been tested successfully in temperatures as low as -70°F and as high as 150°F. While all wooden mats can be slippery in wet, muddy, and icy conditions, the solid top of SiteSafe™ CLT access mats makes removing mud, snow, or ice much easier. Once SiteSafe™ CLT access mats are traveled on, they become well-seasoned, mitigating slickness in challenging conditions.

CAN A SITESAFE™ CLT ACCESS MAT BE REPAIRED, OR DOES IT NEED TO BE DISPOSED OF ONCE DAMAGED?

Since SiteSafe™ CLT access mats are a solid block of wood, necessary repairs can be done easily and are less expensive than with bolted access mats. Repairs to bolted mats often require removing rusted or bent bolts and fragmented boards. Damaged SiteSafe™ CLT access mats are safer on the jobsite than a damaged bolted mat, as a damaged CLT mat does not expose crews to puncture injuries or equipment damage from broken protruding bolts.

IS IT BEST TO RENT, LEASE, OR BUY SITESAFE™ CLT ACCESS MATS?

WILL THE SITESAFE™ CLT ACCESS MATS DELAMINATE OR FALL APART?

SiteSafe™ CLT access mats are constructed with rapid-growth southern yellow pine #2 grade kiln-dried lumber, along with a moisture-activated polyurethane adhesive. The wood’s existing water helps cure the adhesive, creating an exceptional bond. Independent laboratories, including the USDA Forest Products Laboratory, San Diego State University, and Henkel Adhesives, have validated the strength and durability of SiteSafe™ CLT products.